- UD500

- Coverage Area: 1800 sq. ft.

- Noise 10-15dB

- Do not dump

- No water added

- Only support pure plant essential oils

- 2500mA-Can work continuously for 15 hours

- Size:125*75*75mm

- capacity:15ml

- Material: ABS+PA6

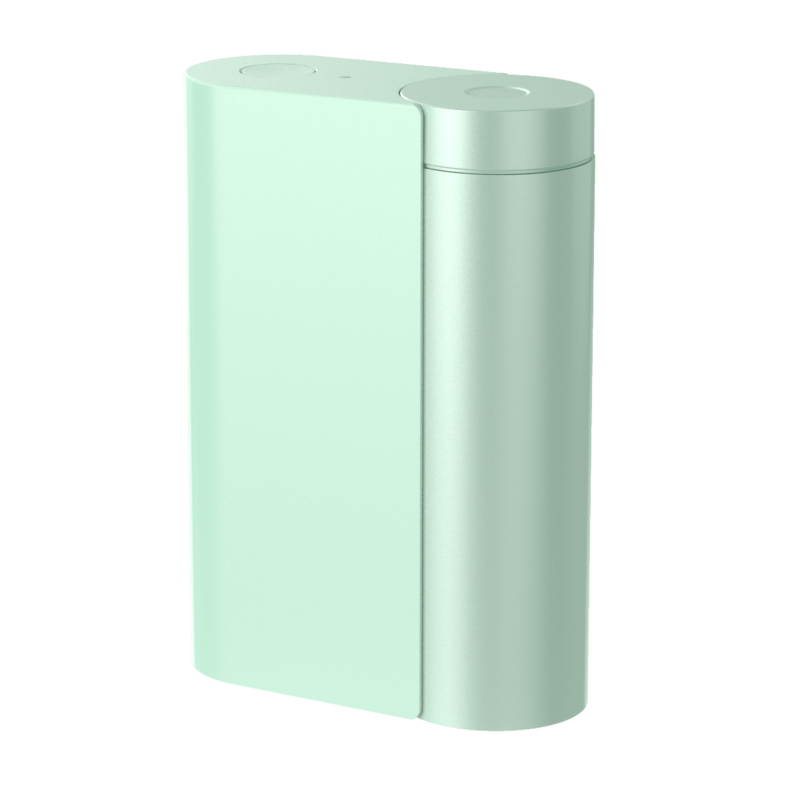

- UD10

- Coverage Area: 1500 sq. ft.

- Noise 10-15dB

- Pourable, carry with you

- No water added

- Only support pure plant essential oils

- 2500mA-Can work continuously for 18 hours

- Size:100*70*30mm

- capacity:8ml

- Material:MPP

- UD11

- Coverage Area: 400 sq. ft.

- Noise 10-15dB

- Pourable, carry with you

- No water added

- Only support pure plant essential oils

- 950mA-Can work continuously for 9 hours

- Size:107*45*22mm

- capacity:5ml

- Material:Aluminum Alloy+PA6

The finest mist

Average 647 nanometers of micro-atomized particles

We primarily recommend this newly launched Ultra-High Frequency Atomized Nano Floating Particle Aromatherapy Diffuser. It is exceptionally remarkable, fulfilling nearly all your expectations of an essential oil diffuser, particularly in terms of its fragrance dissemination technology. To my knowledge, there is no better option available. Friends interested in the aromatherapy business can reach out to us to request samples.

Test Report

Why choose ultra-high frequency essential oil diffuser

There are many types of aromatherapy diffusers on the market. How can we judge whether an Essential oil diffuser is good enough?

First, let’s start with the most basic principle: how do we perceive smells? Smells are transmitted in the form of gaseous molecules. When these molecules enter the nasal cavity, they interact with the olfactory receptors and stimulate the olfactory nerves. Each odor molecule corresponds to a different olfactory receptor, allowing us to distinguish different odors. Essentially, odor molecules entering the nasal cavity trigger the olfactory nerves, allowing us to detect odors.

Analyzing the Essential oil diffuser Based on Principles

An outstanding aromatherapy machine must finely atomize natural essential oils, allowing the particles to float in the air and travel further with indoor airflow, achieving wide fragrance dissemination, long-lasting retention, and high essential oil utilization. It must preserve the original flavor of natural essential oils and utilize cold aroma atomization technology, as mixing with water and high-temperature heating can dilute and destroy the fragrance.

Currently, the main technologies in the aromatherapy machine industry include: [1] Ultrasonic Atomization, [2] Microgrid Atomization, [3] Compression Atomization (air pump type, two-fluid) including cold aroma devices, and [4] Heating Atomization (smoke bomb-type atomization, critical atomization). The emerging technology is [5] Ultra-High Frequency Atomization, which directly atomizes oil-soluble essential oils into nano-sized particles. The average size of atomized particles reaches 647 nanometers (a test report will be provided later), and the particles can float in the air for an extended period, restoring the original fragrance of essential oils, ensuring efficient utilization, wide fragrance dissemination, and long-lasting retention.

(1)Ultrasonic atomization diffuser

is simply a humidifier, the cheapest “aromatherapy diffuser”. It can only atomize water, so when using it, you need to drop essential oil into the water tank. In this way, the original flavor of the natural essential oil will be diluted and destroyed, and it needs to be frequently added with water, which is inconvenient to use. The water tank is also prone to breeding bacteria, and there is a risk of respiratory infection if it is used frequently.

(2)Micro-mesh atomization diffuser

is the same as that of the nebulizer in the hospital. It can atomize water and “medicine liquid” into finer particles, but it cannot directly atomize essential oils. It is also necessary to drip the essential oils into the water tank (or use special water-soluble aromatherapy liquid). Moreover, when this technology is applied to the aromatherapy machine, the oil or water-soluble liquid crystals of the essential oils will easily cause blockage of the micro-mesh.

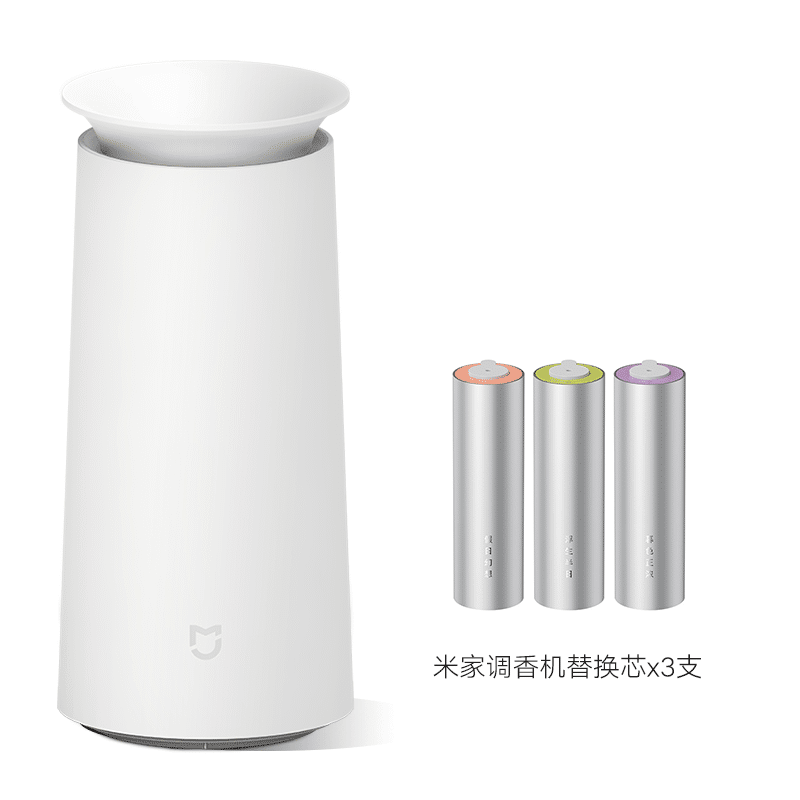

(3)Heating atomization diffuser

such as Xiaomi’s “smoke bomb” aromatherapy diffuser, is actually based on the principle of electronic atomization, which heats the essential oil at high temperature to atomize it. The advantage is that the atomized particles are very small, the fragrance diffusion range is naturally wider, and there is no noise when working. However, the disadvantage is that the high temperature destroys the original flavor of the essential oil, and only special “essential oil bombs” can be used, and other brands of essential oils cannot be used.

(4) Compressed atomization diffuser (dual-fluid technology)

is the most mainstream technology on the market. For example, although the cold aroma instrument can directly atomize pure essential oils, the atomization fineness is not enough and cannot reach the nanometer level. Therefore, although it is relatively close to restoring the original flavor of the essential oils, the problem it brings is that the essential oils are easy to condense and clog at the air outlet. Moreover, because the particles are too heavy and the buoyancy is insufficient, the range of natural fragrance diffusion is small. In addition, a large amount of essential oils will be consumed. When the machine is working, the noise of the air pump is also relatively loud.

(5)Ultra-high frequency atomization diffuser

This new technology is different from the four technologies mentioned above. Its characteristics are that it does not require an air pump or heating, and can directly atomize essential oils at the nano level, and the average diameter of the essential oil particles is 647 nanometers.

Therefore, it brings the following advantages:

1. The essential oil particles are smaller and can float in the air, which can expand the fragrance range, last longer, and save precious essential oils;

2. Because it does not require high-temperature heating or water blending, cold fragrance atomization will not destroy the fragrance of the essential oil, and the essential oil restoration degree is very high;

3. Because it does not require an air pump, it does not generate noise during work, and it works completely without noise, which will not disturb sleep or work.

Moreover, it can be used wirelessly or plugged in to meet the needs of various scenarios.

OEM Support

MOQ

Only 1000 pieces are needed to complete your product OEM

Customized Packaging

Free design-Including kraft paper packaging, color box packaging, blister packaging...

Customized LOGO

Screen printing, Laser printing, Hot stamping, Inkjet printing, UV printing, Thermal transfer

Custom settings

Change the spray time, add APP...

Customized colors

Create differentiated product colors

Custom scent

Compound essential oils are formulated to imitate the scent of big-name perfumes...

ODM Support

MOQ

Only 1K pieces are needed to complete your product ODM

Free design

Our designers will combine the customer's ideas to create product design drawings. Free one design

Customized product features

Customization, for example: spray size, timing, capacity, APP software functions,Battery capacity, light, music, smart home...

Custom scent

Compound essential oils are formulated to imitate the scent of brand perfumes...

Excellent service

From design to delivery, we control every detail

Savings on mold costs

When the product production reaches 500K pieces, you will receive a full refund of the mold fee.